Commercial Metal Roofing offers great value to businesses by providing a long-term solution that is both durable and energy-efficient. There are a variety of metal roofing systems to choose from, each offering its own benefits and drawbacks. Here are the 14 metal roofing types commonly used in commercial applications.

1. Standing Seam Metal Roofing

Standing seam metal roofing is a sleek and modern option for commercial buildings. Fabricated from steel or aluminum, these panels feature interlocking seams that prevent water from penetrating the roof. The panels are available in various gauges, from 24 to 22, and can be custom-fit to suit various building designs. This type of roofing is ideal for low-sloped or flat roofs, such as those found in office buildings, schools, and hospitals. Standing seam panels are typically installed using concealed fasteners attached to the roof deck with clips to ensure a clean, finished look.

- Panel width: typically 12-24 inches

- Panel length: can be custom-fabricated to any length

- Panel thickness: 22-24 gauge

- Material options: steel, aluminum, copper, zinc

Learn about Standing Seam Metal Roofing Installation.

2. R-panel Metal Roofing

R-panel Metal Roofing is a cost-effective and low-maintenance option for commercial buildings. Manufactured from galvanized steel or aluminum, these panels come in gauges ranging from 26 to 22, making them a versatile choice for a wide range of roofing applications. R-panel metal roofing is well-suited to both low-sloped and steep-sloped roofs, making it a popular choice for industrial buildings, retail stores, and restaurants. The panels are installed using exposed fasteners and overlap one another to create a water-resistant barrier that protects the roof from the elements.

- Panel width: typically 36 inches

- Panel length: can be custom-fabricated to any length

- Panel thickness: 22-26 gauge

- Material options: galvanized steel, aluminum

3. Corrugated Metal Roofing

Corrugated metal roofing is a durable and versatile option for commercial buildings. These panels are made from steel or aluminum and feature a wavy pattern that provides added strength and durability. Available in a range of gauges, from 29 to 22, corrugated metal roofing is well-suited to various building designs and is often used for agricultural or industrial applications. The panels can be installed using exposed or concealed fasteners, depending on the desired aesthetic and level of water resistance.

- Panel width: typically 26-36 inches

- Panel length: can be custom-fabricated to any length

- Panel thickness: 22-29 gauge

- Material options: steel, aluminum

4. Metal Shingle Roofing

Metal Shingle Roofing is a stylish and durable option for commercial buildings. These panels mimic the look of traditional roofing materials, such as slate or tile, while providing the added durability and energy efficiency of metal. Metal shingles are available in various shapes and sizes, making them a versatile choice for a range of building designs. These panels are typically installed using exposed fasteners and can be attached directly to the roof deck or over an existing roof.

- Shingle size: typically 12-16 inches long and 8-12 inches wide

- Shingle thickness: 24-26 gauge

- Material options: steel, aluminum

5. Metal Tile Roofing

Metal tile roofing is a durable and aesthetically pleasing option for commercial buildings. These panels are made from steel or aluminum and feature a classic tile design, providing added durability and energy efficiency. Metal tiles are available in various sizes and can be custom-fit to suit various building designs. This type of roofing is well-suited to steep-sloped roofs and is often used in residential or commercial buildings with a traditional or Mediterranean aesthetic. Metal tiles are typically installed using concealed fasteners, creating a clean and seamless look.

- Tile size: typically 16-18 inches long and 12-14 inches wide

- Tile thickness: 24-26 gauge

- Material options: steel, aluminum

6. Snap-Lock Metal Roofing

Snap-lock metal roofing is a low-maintenance and easy-to-install option for commercial buildings. These panels feature a snap-together design, eliminating the need for exposed fasteners and reducing the risk of leaks. Snap-lock panels are typically made from steel or aluminum and are available in a range of gauges, from 24 to 22. This type of roofing is well-suited to low-sloped roofs and is often used in residential or commercial buildings with a modern or minimalist design.

- Panel width: typically 12-16 inches

- Panel length: can be custom-fabricated to any length

- Panel thickness: 22-24 gauge

- Material options: steel, aluminum

7. Batten Seam Metal Roofing

Batten seam metal roofing is a stylish and durable option for commercial buildings. These panels feature raised seams attached to the roof deck using battens, creating a distinctive, ribbed appearance. Batten seam panels are typically made from steel or aluminum and are available in gauges ranging from 24 to 22. This type of roofing is well-suited to steep-sloped roofs and is often used in residential or commercial buildings with a traditional or industrial aesthetic.

- Panel width: typically 12-16 inches

- Panel length: can be custom-fabricated to any length

- Panel thickness: 22-24 gauge

- Material options: steel, aluminum

8. Flat-Lock Metal Roofing

Flat-lock metal roofing is a versatile and durable option for commercial buildings. These panels feature flat interlocking seams, which create a smooth, uniform appearance on the roof. Flat-lock panels are typically made from copper or zinc but can be fabricated from steel or aluminum. This type of roofing is well-suited to low-sloped roofs and is often used in residential or commercial buildings with a contemporary or modern design.

- Panel width: typically 12-16 inches

- Panel length: can be custom-fabricated to any length

- Panel thickness: 22-24 gauge

- Material options: copper, zinc, steel, aluminum

9. Aluminum Standing Seam Metal Roofing

Aluminum standing seam metal roofing is a lightweight and durable option for commercial buildings in coastal or high-humidity environments. Aluminum panels are corrosion-resistant and can withstand exposure to salt water and other harsh elements. This type of roofing is well-suited to low-sloped or flat roofs and is often used in commercial buildings near the coast or in humid environments. Aluminum standing seam metal roofing is typically installed using concealed fasteners, creating a seamless and clean look on the roof.

- Panel width: typically 12-24 inches

- Panel length: can be custom-fabricated to any length

- Panel thickness: 22-24 gauge

- Material options: Aluminum

10. Modular Press-Formed Panels

Modular press-formed panels are made by pressing a flat sheet of metal into a series of modules with ribs or ridges, which add strength to the panel. These panels can be fabricated from a range of metals, including steel, aluminum, and copper, and are available in various sizes and colors. Modular press-formed panels are typically installed using exposed fasteners and are suitable for low and steep roofs.

- Panel width: typically ranges from 12″ to 16″

- Panel length: typically custom-fabricated to project specifications

- Panel thickness: 18 – 24 gauge

- Material options: steel, aluminum, copper, zinc

11. Tapered Metal Roofing

Tapered metal panels are designed to slope gradually from one end to the other, creating a water-shedding surface that effectively prevents leaks. This type of roofing is often used on flat or low-sloped roofs. These panels are custom fabricated to match the roof’s slope, ensuring proper drainage of rainwater. Tapered metal roofing panels are typically made from steel or aluminum and can be installed using concealed or exposed fasteners. These panels are well-suited to low-sloped roofs in commercial and industrial buildings.

- Panel width: typically ranges from 12″ to 24″

- Panel length: typically custom-fabricated to project specifications

- Panel thickness: 18 – 24 gauge

- Material options: steel, aluminum, copper, zinc

12. Insulated Metal Panels

Insulated metal panels are designed to provide roofing and insulation in a single product, making them an efficient and cost-effective option for commercial buildings. These panels are typically made from a layer of metal sandwiched between two layers of insulation material, such as polyurethane foam or mineral wool. These panels can be installed using concealed or exposed fasteners and are well-suited to commercial and industrial buildings that require improved energy efficiency and weather resistance.

- Panel width: typically ranges from 24″ to 48″

- Panel length: typically custom-fabricated to project specifications

- Panel thickness: typically ranges from 2″ to 6″

- Material options: steel or aluminum skins with a foam core (polyisocyanurate or expanded polystyrene)

13. Copper Roofing

Copper is a premium roofing material known for its durability, longevity, and unique aesthetic appeal. Copper panels are made from 100% copper and can be fabricated into various shapes and sizes to suit different building designs. Over time, copper roofing will develop a patina with a distinctive greenish-blue appearance. Copper roofing is well-suited to steep-sloped roofs and is often used in residential or commercial buildings with a traditional or historical aesthetic.

- Panel width: typically 12-16 inches

- Panel length: can be custom-fabricated to any length

- Panel thickness: 16-24 gauge

- Material options: copper

14. Zinc Roofing

Zinc roofing is a long-lasting, low-maintenance material that offers a unique, silvery-gray appearance. Zinc panels are made from 99% pure zinc and are typically installed using concealed fasteners, creating a clean and seamless look on the roof. Zinc roofing is well-suited to both low-sloped and steep-sloped roofs and is often used in residential or commercial buildings with a contemporary or modern design. Over time, zinc roofing will develop a natural patina that protects the metal and gives it an amber hue.

- Panel width: typically 12-16 inches

- Panel length: can be custom-fabricated to any length

- Panel thickness: 24 – 32 gauge

- Material options: zinc

Note: The Specifications for all of the metal roofing systems may vary slightly depending on the manufacturer. When selecting a system for your project, it is important to check with the manufacturer. Additionally, installation instructions should be followed closely to ensure proper installation and performance. Professional installation is recommended for all metal roofing systems.

Benefits of Metal Roofing

Metal roofing provides many benefits for commercial buildings, including

- Durability: Metal roofing is highly durable and can last decades when properly maintained.

- Energy Efficiency: Metal roofs reflect sunlight, helping to reduce energy costs.

- Low Maintenance: Metal roofs require minimal maintenance and repairs over their lifetime.

- Fire Resistance: Metal roofing is non-combustible, providing extra protection in the case of fire.

- Weather Resistance: Metal roofs are highly resistant to extreme weather conditions such as high winds, hail, and heavy snow.

- Aesthetics: Metal roofing comes in various colors and styles, allowing for more design flexibility than other materials.

While metal roofing offers several benefits, it’s essential to consider its limitations when choosing the right type for your commercial building.

Some of the limitations include:

- Expansion and Contraction: Metal roofing expands and contracts with temperature changes, which can cause the panels to buckle or warp over time.

- Noise: Metal roofing can be noisy during heavy rain or hail storms, which can be a concern for commercial buildings that require a quiet environment.

- Cost: While metal roofing is a cost-effective option in the long run, it can be more expensive upfront than traditional roofing materials like asphalt shingles.

Commercial Metal Roofing FAQs

When properly cared for and maintained, a commercial metal roof can last 40 years, surpassing the standard 25-year lifespan. Maximize your investment with simple maintenance steps every few months to keep it in tip-top condition!

When considering commercial metal roofing, there are a few factors to take into account. Firstly, consider the lifespan of a metal roof and whether it would be worth the investment in the long run. Additionally, think about how much energy your business spends on heating and cooling, as a metal roof can help to reduce energy costs. It’s also important to weigh the pros and cons of metal roofs versus other roofing options to determine which would be the best fit for your business.

Contrary to popular belief, metal roofs do not attract lightning. Research has actually shown that metal roofs are just as safe as other types of roofing materials when it comes to lightning strikes.

Although metal roofs are highly resistant to leaks, no roof is completely leak-proof. It’s essential to have any leaks repaired promptly to prevent further damage.

During the installation of a metal roof, it’s recommended to overlap each panel by at least two inches. This ensures a tight seal and helps to prevent leaks.

In conclusion, metal roofing is an excellent option for commercial buildings due to its durability, energy efficiency, and low maintenance. By understanding the different types of commercial metal roofing and their suitability for different building types, you can choose the right option that meets your building’s needs and budget. With regular inspections and maintenance, your metal roof can last for many years and provide reliable protection for your commercial building.

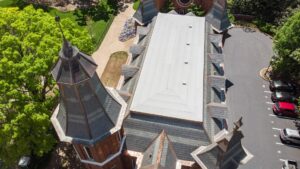

At Eskola, we provide a wide range of commercial metal roofing solutions. Our team is highly experienced in installing metal roofs and can help you find the right product for your building. We have an in-house sheet metal fabrication shop to provide custom metal roofing solutions, and our experienced technicians offer professional installation services. We also provide regular maintenance and repair services for all metal roofing systems.

View our Commercial Roofing Projects to witness the high-quality craftsmanship that we bring to each task.

Vanderbilt Student Health Center

Pigeon Forge Trolley Station

Clay City Elementary School

CBRE

Baylor School

United Methodist Hospital Memphis

Baptist Surgical Center

Greenville SC Manufacturing

Ascension Saint Thomas Hospital

Baptist 86 Tower

Middle Tennessee University

1880 Historical Vanderbilt University Gymnasium

Are you ready to get started on your metal roofing project? Contact Eskola today and get a free estimate and consultation! Our team of experts will work with you to find the best solutions for your commercial building. We’ll provide detailed information about all of our products, services, and prices so you can make an informed decision.