In the vast realm of roofing, especially for commercial buildings with low-slope roofs, two materials have consistently risen to prominence: TPO roofing and PVC roofing. Both have their unique strengths, histories, and applications. This comprehensive guide aims to shed light on these two materials, helping property owners make an informed decision.

The Rise of TPO Roofing (Thermoplastic Polyolefin)

Over the past few decades, TPO roofing has emerged as a popular choice for commercial buildings. Its blend of polypropylene and ethylene-propylene rubber offers a robust and durable roofing solution. This combination is further enhanced with a polyester mat, UV light inhibitors, and other elements that contribute to its resilience.

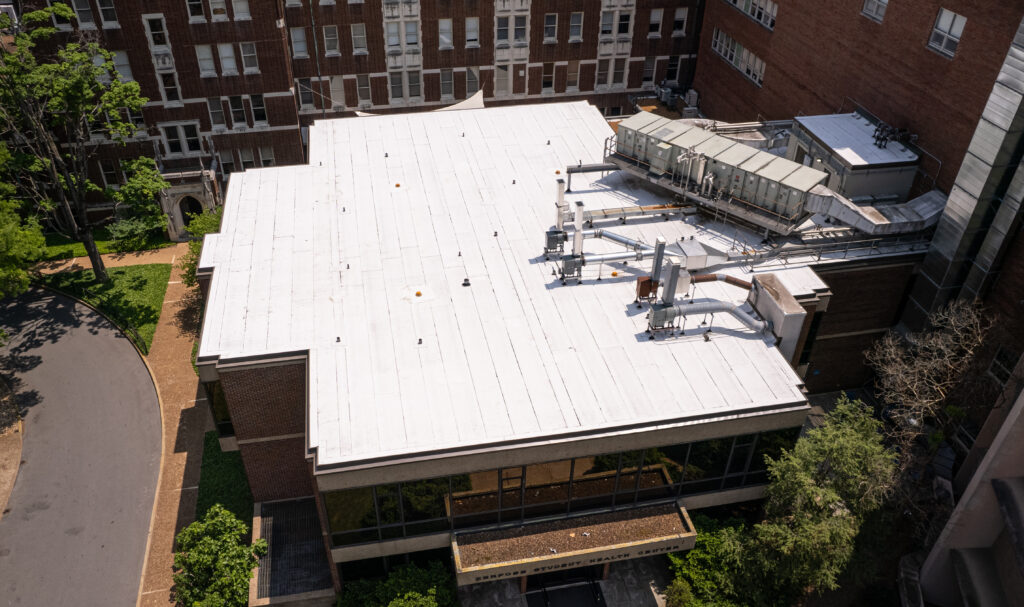

When you encounter a TPO roof, you’re witnessing the result of meticulous engineering. The sheets, which originate from rolls typically ranging from 6-16 ft in width, are laid out seamlessly to cover vast expanses. The heat-welded seams of TPO are its first line of defense against leaks, ensuring that water intrusion remains a distant concern.

But TPO isn’t just about protection; it’s also about aesthetics and environmental responsibility. Available in various hues, it can complement a building’s architecture while its UV resistance reduces heat absorption, leading to potential energy savings. Furthermore, its potential contribution to LEED credit qualifications underscores its eco-friendly nature.

PVC Roofing (Polyvinyl Chloride): A Time-Tested Solution

PVC roofing has been a stalwart in the roofing industry for over six decades. Its dual-layered construction, with a polyester reinforcement layer sandwiched between two PVC layers, offers both durability and flexibility. This design ensures the top layer remains resilient against the sun’s harsh UV rays, while the bottom layer retains a flexibility that installers appreciate.

Like TPO, PVC also boasts heat-welded seams, ensuring a watertight seal. Its resistance to chemicals and fire makes it a safe choice for various industrial applications. Moreover, in today’s eco-conscious world, PVC’s recyclability stands out, offering a nod to sustainability.

TPO vs PVC: A Comparative Analysis

Material Composition and Durability

TPO, a blend of polypropylene and ethylene-propylene rubber, is celebrated for its robustness and flexibility. In contrast, PVC, known for its rigidity, offers commendable strength and durability. While both are designed to combat the detrimental effects of UV rays, TPO often emerges superior in UV resistance. This advantage can translate to reduced cooling costs in sun-drenched regions.

In the arena of tear and break strength, TPO generally outshines PVC. This makes TPO a favored choice for roofs subjected to heavy foot traffic or environmental challenges.

Chemical Resistance

Both materials are crafted to endure a myriad of environmental factors. However, there’s a distinction in their chemical resistance. TPO might exhibit adverse reactions to specific oils or exhausts, posing concerns for buildings in proximity to restaurants or certain industrial areas. In contrast, PVC stands its ground, remaining predominantly non-reactive, which can be a boon for such environments.

Cost Analysis

Cost often becomes the deciding factor for many. Here’s how TPO and PVC compare:

Initial Installation Costs: TPO usually offers a more wallet-friendly cost per square foot, rendering the initial installation more economical than PVC. However, prices can fluctuate based on region, labor charges, and the particular product selected.

Maintenance and Repair: Both materials boast durability, but when repairs are in order, TPO often proves more cost-effective. This is attributed to its widespread availability and the inherent nature of the material.

Longevity and Replacement: While PVC roofs, with diligent maintenance, might outlive TPO roofs, the replacement costs over a building’s lifespan can tilt the scales. TPO, with its lower upfront installation cost, might present better value in the long run.

Energy Efficiency and Utility Costs: TPO’s enhanced UV resistance can lead to tangible savings on cooling, especially in sunnier locales. Over an extended period, these savings can bridge the initial cost disparity between TPO and PVC.

Environmental Considerations

From an environmental perspective, both materials have their merits. PVC is recyclable, positioning it as an eco-conscious choice at its lifecycle’s end. On the other hand, TPO, with its potential to contribute to LEED credit qualifications, stands out for businesses eyeing green certifications.

Factors Influencing the Choice

Beyond the material properties, several external factors play pivotal roles in the selection process:

1. Building’s Purpose and Usage: The function of the building can significantly impact the choice of roofing material. For instance, an industrial facility with heavy machinery might produce oils and exhausts that can affect TPO. In contrast, a commercial space like a mall or office might not have such concerns.

2. Geographic Location and Climate: The building’s location can dictate the roofing material. In areas with intense sunlight, TPO’s superior UV resistance can be beneficial. For regions experiencing heavy rainfall, the waterproofing capabilities of both materials will be crucial, but the chemical resistance of PVC might be preferred in areas with acidic rain.

3. Budgetary Constraints: While both TPO and PVC offer long-term benefits, their initial costs differ. TPO generally comes in as the more budget-friendly option in terms of installation. However, considering the lifespan and maintenance costs, PVC might offer better value in some scenarios.

4. Building Aesthetics and Design: The visual appeal of the roofing material can be a deciding factor, especially for commercial spaces where branding and aesthetics are crucial. Both TPO and PVC come in various colors, but specific shades or finishes might sway the decision.

5. Environmental and Sustainability Concerns: For businesses and property owners keen on sustainability, the environmental impact of the roofing material is paramount. PVC’s recyclability might appeal to those looking for eco-friendly solutions, while TPO’s potential contribution to LEED credits can be a draw for others.

6. Longevity and Durability Needs: If the goal is to install a roof that requires minimal intervention for decades, understanding the lifespan and durability of each material becomes essential. While both materials are durable, factors like foot traffic, exposure to chemicals, and the likelihood of physical damage can influence the choice.

7. Maintenance and Repair Considerations: Over time, all roofs require some form of maintenance or repair. The ease of maintenance, availability of materials, and cost of repairs for TPO and PVC can differ, influencing long-term commitments.

8. Local Building Codes and Regulations: Sometimes, the choice might be influenced by local building codes, regulations, or even incentives. Certain areas might have regulations favoring materials with specific fire resistance ratings or energy efficiency standards.

9. Warranty and Manufacturer Reputation: The warranties offered by manufacturers can be a significant factor. A more extended warranty might tip the scales in favor of one material. Additionally, the reputation and reviews of the manufacturer can influence trust and, ultimately, the decision.

FAQs on TPO Roofing

1. What is TPO roofing?

TPO, or Thermoplastic Olefin, is a type of single-ply roofing membrane. It’s a popular choice for commercial roofing systems due to its durability, energy efficiency, and cost-effectiveness.

2. What does TPO roofing stand for?

TPO stands for Thermoplastic Olefin.

3. How long do TPO roofs last?

TPO roofs typically last between 15 to 20 years, depending on factors like installation quality, maintenance, and environmental conditions.

4. How to repair TPO roofing?

TPO roofing can be repaired using TPO-specific patches, seam tapes, or specialized welding equipment to fuse the material together.

5. What is TPO roofing material made of?

TPO roofing material is made from a blend of polypropylene and ethylene-propylene rubber.

6. Can you paint TPO roofing?

While TPO roofing can technically be painted, it’s essential to use the right type of paint and primer to ensure proper adhesion and longevity.

7. Is TPO roofing good?

Yes, TPO roofing is known for its durability, energy efficiency, and cost-effectiveness, making it a popular choice for many commercial buildings.

8. What is the best TPO roofing material?

The “best” TPO roofing material can vary based on specific needs, but reputable manufacturers like GAF, Carlisle, and Firestone are known for producing high-quality TPO membranes.

9. Is TPO roof glued down?

TPO roofing can be installed using various methods, including being fully adhered (glued down), mechanically attached, or ballasted.

10. How thick is TPO roofing?

TPO roofing membranes typically range in thickness from 45 mils to 80 mils.

11. How to apply TPO roofing?

TPO roofing is applied by rolling out the membrane, positioning it, and then welding the seams using hot air welding equipment.

12. What colors does TPO roofing come in?

While white is the most common color for TPO roofing due to its reflective properties, it also comes in other colors like grey, tan, and black.

13. Is TPO roofing fire-resistant?

Yes, TPO roofing is designed to be fire-resistant and meets various fire codes when installed correctly.

14. Can TPO roofing be installed over plywood?

Yes, TPO roofing can be installed over plywood, but it’s essential to use an appropriate underlayment or insulation layer between the plywood and the TPO membrane.

15. How to seal TPO roofing?

TPO roofing seams are sealed using hot air welding equipment, which fuses the material together to create a watertight seal.

16. Is TPO roofing flammable?

While TPO roofing is designed to be fire-resistant, like all roofing materials, it can catch fire under extreme conditions. Proper installation and adherence to building codes can minimize this risk.

17. How to weld TPO roofing?

TPO roofing is welded using specialized hot air welding equipment, which melts the material at the seams and fuses it together.

FAQs on PVC Roofing

1. How long does a PVC roof last?

PVC roofs typically last between 20 to 30 years, depending on factors like installation quality, maintenance, and environmental conditions.

2. Is PVC roofing good?

Yes, PVC roofing is known for its durability, chemical resistance, and fire resistance, making it a popular choice for many commercial buildings.

3. What problems does PVC roofing faces?

Some potential problems with PVC roofing include shrinking of the membrane, punctures, and seam failures. However, with proper installation and maintenance, these issues can be minimized.

4. What does PVC roofing look like?

PVC roofing typically has a smooth, white surface, although it can come in other colors. Its appearance is similar to other single-ply membranes but is distinguishable by its texture and finish.

5. How is PVC roofing installed?

PVC roofing is installed by rolling out the membrane, positioning it, and then welding the seams using hot air welding equipment.

6. How much is PVC roofing?

The cost of PVC roofing can vary based on factors like region, labor costs, and the specific product chosen. It’s best to get quotes from local contractors for accurate pricing.

7. Can you walk on PVC roofing?

While PVC roofing is durable, it’s essential to walk on designated walk pads or areas reinforced for foot traffic to avoid damaging the membrane.

8. What is PVC roofing material?

PVC roofing is a single-ply roofing membrane made from polyvinyl chloride, combined with plasticizers, stabilizers, and other components to enhance its flexibility and durability.

9. Pros and cons of PVC roofing?

Pros:

- Durable and long-lasting

- Resistant to chemicals and fire

- Energy-efficient due to its reflective properties

Cons:

- Can be more costly than other materials

- Potential for seam failures if not installed correctly

- Not as flexible as some other single-ply membranes

The debate between TPO roofing and PVC roofing isn’t about determining a clear winner. It’s about understanding the nuances of each material and aligning them with a building’s specific needs. Both materials have proven their worth in the field, and the choice often boils down to specific requirements, budgetary constraints, and long-term goals.